The Story of James E. Bennett, Jr.

in his own words

Chapter 4

Starting a Family - Fall 1946 To Summer 1958

Starting a Family - Fall 1946 To Summer 1958

Jim and Kathryn at Myrtle Beach

Jim and Kathryn at Myrtle Beach

I enrolled back at N. C. State and started school in the Fall of 46. I dated Kathryn several times during the summer. Kathryn had completed Erskine College in three years and was working at American Cyanamid as a chemist, as she had a major in Chemistry and a minor in Math from Erskine. I went back to State in September, 1946 on the G I Bill. The Bill paid for tuition and $60.00 per month. I had to repeat most of my class work that I had in 1943. I had a very hard time in English. I attended Summer School, 1947, taking a surveying course and other courses. I had started dating Kathryn seriously.

During the summer of 1947, Kathryn and a group of girl friends from the college days were spending a week at a S.C. beach near Myrtle Beach, SC. I hitchhiked down from Raleigh and we became engaged to be married in the summer of 1948.

During the summer of 1947, Kathryn and a group of girl friends from the college days were spending a week at a S.C. beach near Myrtle Beach, SC. I hitchhiked down from Raleigh and we became engaged to be married in the summer of 1948.

Kathryn's father was a minster at Back Creek Associate Reformed Presbyterian Church in Newell, N.C.. Back Creek was his first church after graduation from the Associate Reformed Presbyterian Seminary at Erskine College in 1918. He stayed at the home of Mr. and Mrs. Garrison of Newell, NC. There he met Macie, their daughter, who was teaching school in Alabama during that time. Dr. Stroup married Macie in January, 1920, and they moved into the church manse. Kathryn will have to provide the information on the Garrison/Stroup side of the family.

Jim and Kathryn wedding

Jim and Kathryn wedding

We were married in his Church on August 28, 1948. It was the hottest day of the summer of 1948. My sister Edith, the oldest, was already married to Gene Kirk also from the Newell area. Kathryn was the first one to get married in her family (Paul and David were older). Her brother, Paul, a dentist did a lot of work on my teeth at no cost to me as part of his wedding present to Kathryn.

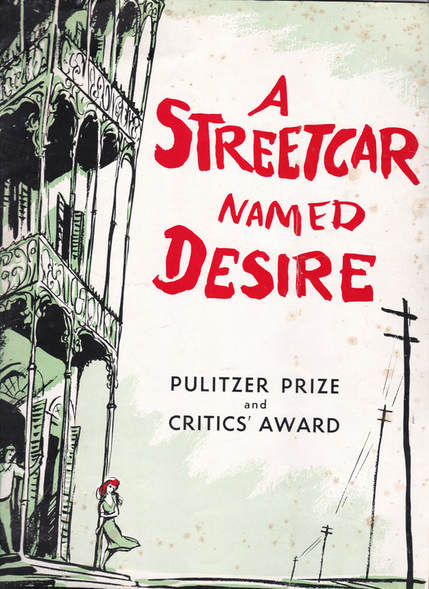

I still had two more years at State. We went to New York City for our Honeymoon. Dad let me use his car, a Studebaker, to drive on the honeymoon. Our first night was spent at O' Henry Hotel in Greensboro, NC and the second night in Front Royal, VA on the way to New York City. We stayed at Hotel Taft while in New York City. We went to several radio shows and had our first look at television. We saw two stage plays, "Streetcar Named Desire" staring Marlon Brando and Jessica Tandy and "Annie Get Your Gun". As soon as we were married, I applied for housing in the Veteran's housing area at N.C. State. We were informed that housing would not be available until next year, however they placed our names on the housing list.

In the fall we moved to Raleigh and the only place we could rent was a room in the home of a family where I had stayed my freshman year in 1942-43. The G I monthly went to $75.00 a month for a married couple. Mr. and Mrs. Brigman and their daughter Alma had a large home near the school and they would rent rooms out to the students. We had a screened in porch as a bedroom. The room did not have a private bath or a kitchen. We ate all our meals out. Kathryn starting looking for a job as soon as we got to Raleigh. She applied at State and several other places. She ended up with a job working for North Carolina Fire Insurance Rating Bureau at $140.00 per month. Not long after she began to work, State College called and offer her a position to teach freshmen chemistry lab. She declined. We had no car and she either rode the city bus or walked to and from work. Kathryn become pregnant in September and we waited until January to tell Mrs. Brigman. She asked us to find another place to live, as we would be a bad influence on Alma, her 16 year old daughter. Kathryn immediately started looking for a place to stay. I believe that she called every home within walking distance of the college until she found a room with kitchen privileges. The owner of the home was a retired couple. He had retired from North Carolina state prison system and his idea of an exciting day was to be a witness at a State execution. He would always ask me to go with him, but I never did.

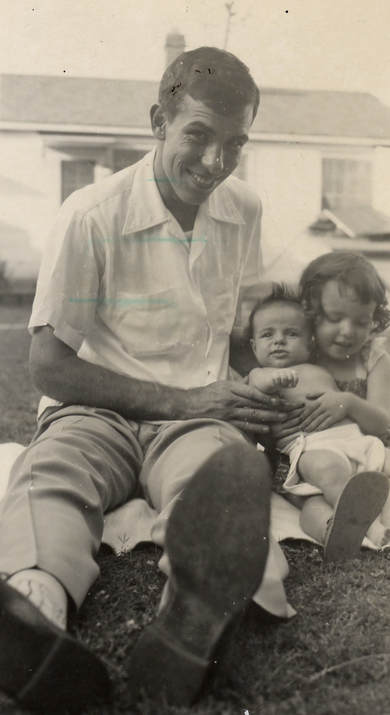

Jim and Kathryn with Kathy at Vetville

Jim and Kathryn with Kathy at Vetville

Kathryn worked until six weeks before our first child was due. Her doctor recommended walking, so she walked the two miles to and from our room to the Rating Bureau in downtown Raleigh each day. Kathy was born during exam week on Flag Day, June 14, 1949. The G I monthly jumped to $90 when Kathy was born and this was payable only during the school year. I finished up the school year and we spent the summer in Charlotte at the insistence of my family. We stayed with them and I worked part of the summer at very little pay. We received notice from State College that they had a place for us in Vetville starting with the fall of 1949.

Vetville was composed of converted army barracks. The barracks were rectangular in shape, either one or two stories and subdivided into either two or three bedrooms units. We had a two bedroom unit, composed of two bedrooms, kitchen, bathroom, and a living room with a space heater in the living room to heat the entire area. The floors were very rough and Kathryn kept Kathy either in a play pen or the bassinet most of the time until she started walking, which she did at nine months. The kitchen was not very well equipped. We had an ice box instead of a refrigerator and a kerosene stove to cook on. We furnished the unit with old furniture from various place, but it was home.

In the summer of 1947 Kathryn's father accepted the pastorate of an ARP church in Memphis, TN, and in the process of the move the moving van ran off a mountain road, rolling over and caught fire destroying the moving van. The Stroup's lost all their belonging as well as Kathryn's wedding dress.

Kathy between Paul and Lib in Paul's convertible

Kathy between Paul and Lib in Paul's convertible

Paul, her older brother, was married by that time and they had a red Buick Roadmaster convertible. When Kathy was about two and half months old, Paul and Kathryn decided to visit their parents. We all five, Paul, his wife Lib, Kathryn, Kathy and I got into the Buick and we drove from Charlotte to Memphis and back. We put Kathy in a bassinet that sat on the back seat wedged in by the front seat. We spent the weekend with them and drove back to Charlotte. While we were in Memphis we crossed the Mississippi River. On the way back we went by Nashville to see David who was at Vanderbilt studying medicine. We met Betty, to whom he was engaged. By the time we got back to Charlotte Kathy had been in seven states at a very early age.

We had a good time in Vetville, as no one had any money. All we had was the GI bill which paid for the tuition and so much a month. We did not ask for any help from our parents. The end of the month came with only pennies left over. There was no extra money, and Kathryn was excellent at making ends meet and still have food on the table. Only a few of the veterans had cars.

Jim at graduation with Elizabeth, Jim Sr., and Kathryn

Jim at graduation with Elizabeth, Jim Sr., and Kathryn

I graduated in June, 1950 and moved back to Charlotte. I didn't have a job, but two possibilities. One was with the Memphis electrical utility that Dr. Stroup was responsible for setting up, but I didn't want to move to Memphis and the second one was with David's wife's father who had several businesses outside of Atlanta, Georgia. He had a building supply house and was looking for someone to run it. That may have been the best choice, but I was afraid of working in a family situation. Kathryn and Kathy went out to Memphis to visit her parents and I stayed in Charlotte to look for work. I found a position as a trainee for Horne Wilson, a plumbing and heating supply house.

While waiting to start to work, I drove my dad on one of his routes and I drove through a smoke cloud along the road. Some farmer was burning along the road side, and I later broke out with poison ivy on the entire left side of my face and my left arm up to the sleeve line. The face was so swollen that I had to go to the hospital. I was in the Charlotte Memorial Hospital for seven (7) days. The bill was as follows:

Room: 7 days @ $7.00 per day for $49.00

Lab Work: $34.10

Drug Cost: $12.95

Total: $96.05.

We had no health insurance. After getting out of the hospital and the swelling gone, I went to work at Horne Wilson in July, 1950 for $170.00 a month in a sales trainee program.

Room: 7 days @ $7.00 per day for $49.00

Lab Work: $34.10

Drug Cost: $12.95

Total: $96.05.

We had no health insurance. After getting out of the hospital and the swelling gone, I went to work at Horne Wilson in July, 1950 for $170.00 a month in a sales trainee program.

The training period consisted of working in the various areas of the business before becoming a salesman selling plumbing and heating materials to the various contractors. I started off working in the warehouse loading and unloading pipes, sheet metal, fittings, fixtures, etc.. One of the hardest jobs was learning how to handle the thin 4’ X 8’ large sheet metal plates without cutting your hands on the edges. I also studied how to make takeoffs from the drawings in order to determine what the contractor would need for the job.

We found an apartment on the north side of Charlotte on a bus route. I rode the bus to work and one of the first things we did was to buy a used car from Mr. Brigman of Raleigh. He gave us a very good price and I don't think he made any money on the sale. I believe I paid him around $250.00 for a 1937 Chevrolet. Kathryn could not drive at that time and I instructed her in driving skills after work and on weekends. She learned very quickly and soon had her driving license. I had been working at Horne Wilson for about four months when a friend told me about a job opening he heard about with Froehling and Robertson, a commercial testing laboratory with a branch office in Charlotte. Froehling and Robertson was out of Richmond Virginia with several branch offices in Virginia and North Carolina. I arranged for an interview with Mr. Edwards, the Charlotte Branch Manager. Mr. Edwards offered me a job on the Salisbury Veteran's Hospital Project, which I accepted. The laboratory was responsible for doing the concrete testing and inspection on a very large veterans hospital complex in Salisbury, NC that was just starting in construction.

Kathy and Kathryn in Salisbury, NC

Kathy and Kathryn in Salisbury, NC

We moved to Salisbury in the fall of 1950. Salisbury is about 40 miles north of Charlotte. We rented a nice two bedroom apartment not too far from work. I was furnished a vehicle by Froehling & Robertson and the concrete transit mix company furnished a small office and a laboratory testing area. I performed plant inspection on the transit mixed concrete and took concrete samples at the point of placement for testing. The concrete specimens (6" X 12" cylinders) were water cured in the plant laboratory and transported back to the Charlotte Laboratory to be tested at 7 days and 28 days as I did not have a testing machine to test the specimens for compressive strength. This was the beginning of my long association with concrete.

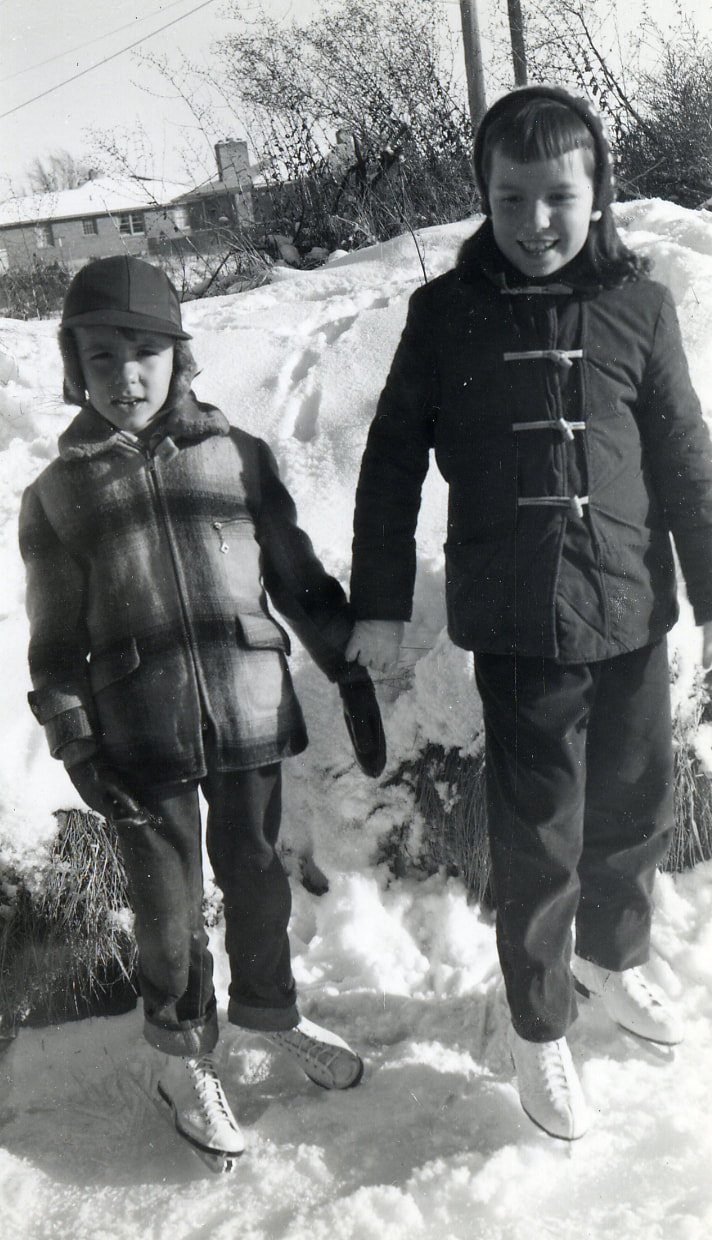

Jim, Jimmy, and Kathy, May 1952

Jim, Jimmy, and Kathy, May 1952

We decided that it was time to have another child. Jimmy was born in Salisbury April 17, 1952. After the project's concrete work was completed in May, 1952, the Richmond office promoted me to Branch Manager and transferred me to their laboratory in Winston Salem, NC. We rented a small apartment in Winston Salem, NC and moved. After a few months it was becoming very apparent to me that there was not enough business to have a branch office and also things were being done that were against good business practices. I strongly recommended that Richmond close the office. They accepted my recommendation and I closed the office down. Kathryn, Kathy and Jimmy spent several weeks with my folks until Richmond decided what to do with me.

I was temporarily sent to Williamsburg, VA where Froehling & Robertson had a concrete inspection contract with the Corps Of Engineers. The army was converting the Camp Eustis facility into a fort. One of the projects going on while I was there was, as far as I know, the construction of the first airport that was designed specifically for helicopters. Kathy came down with the mumps while they were staying in Charlotte, and on one of my visit from Williamsburg to Charlotte I caught them. I flew back Charlotte and I was quite sick for a while, running a very high fever. When I recovered the company transferred me to the home office in Richmond, VA.

Jim, Jimmy, Kathy, and Kathryn coming back from church in Richmond VA, April 1953

Jim, Jimmy, Kathy, and Kathryn coming back from church in Richmond VA, April 1953

We moved to Richmond in July, 1952 and rented a garden apartment. I was furnished a vehicle in my position as Assistant Concrete Manager. I stayed in this position for around three years learning a lot about company procedures, testing of construction materials such as aggregates, soils, cements, water, admixtures, and concrete. The laboratory covered the entire state of Virginia. I spent some time visiting a TVA dam project under construction in Tennessee (John Sevier Dam) as we were bidding on a Stone Webster dam project in Roanoke Rapids in North Carolina. We did get the job of inspecting the concrete at the batch plant and also the testing of the cement. When the contractor was ready to start concreting I went down and set up the inspection procedures. I trained a lead inspector in the art of batch plant inspection and testing of concrete and its constituents at the batch plant.

The company did a lot of inspection in West Virginia during the construction of the West Virginia Turnpike and on a group of hospitals that the Coal Miner's Union was building. John L. Louis, head of the Coal Miner's Union, forced the Turnpike Authority to construct the turnpike with concrete rather than asphalt since the coal mines supplied coal to the cement mills.

April, 1954 visit to see relatives in St. Louis area. Jim and his cousin Lucille, with Jimmy and Kathy

April, 1954 visit to see relatives in St. Louis area. Jim and his cousin Lucille, with Jimmy and Kathy

While living in Richmond, we purchased a double lot where we were planning to build a home. I think we paid $25.00 down and $15.00 a month. It was a new section of land that was being developed in Richmond, not far from our apartment. We held on to the land until we bought our first home in Idaho Falls, ID. Some years later, we were in the area on vacation and we went out and visited the area. There were homes on the majority of the lots, including one on our old lots. In November, 1954 we bought our first new car, a 1954 two door Ford sedan.

In late August, 1955, I was transferred to the Washington D.C. office as the Branch Manager, reporting to the President of Froehling and Robertson, Mr. Ed Doyle. Mother and Dad came up from Charlotte to keep the children while we went to the Washington area to look for a place to live. Kathryn had already registered Kathy to start the first grade in Richmond. We found an apartment in West Hyattsville, Maryland and moved in Labor Day weekend, so Kathy would be able to start school on time. West Hyattsville was just outside the District of Columbia. At work, the company did a lot of inspection of the street and sidewalks in housing developments, so I was very knowledgeable of all new housing developments. Our favorite week-end recreation was visiting the model homes in all the areas in and around Washington.

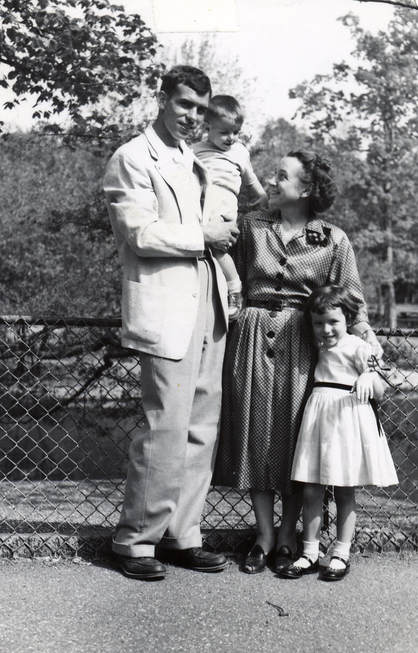

Jim and family in West Hyattsville, MD

Jim and family in West Hyattsville, MD

One of my most interesting projects was the checking of the foundation and walls in the United States Capital building. Another project was conducting a load bearing test on piles driven on a property in Virginia near Washington where Westinghouse was planning to construct a warehouse with extremely heavy floor loadings. The test failed. Prior to buying the land, Westinghouse hired a well known New York engineering firm to conduct a survey of the land to determine if there would be any foundation problems in constructing the building. Based on the engineer's report, Westinghouse purchased the land. While conducting the load testing, I talked to a several people that had been in the area a long time and I found out that years ago the area was a swamp with a small creek running through the land. Over the years the various owners had dumped dirt covering up the area. I told Westinghouse's Resident Engineer. All the soil testing done by the New York firm did not uncover the old swamp area as the drilling and test locations were spread out over the lot. Westinghouse called a meeting with the New York engineering firm. I was in the meeting and had a hard time keeping a straight face listening to the firm's top engineers explaining how they missed the bad foundation. The construction cost due to the poor foundation was considerable more than Westinghouse's construction budget. I was told that they would not have purchased the land if they had known the problems of the foundation. They gave me all the inspections for the project. Another time I was called in to investigate the bucking of an underground silo concrete slab. The concrete slab was around four feet but hydrostatic pressure in ground water buckled and cracked the slab. The engineer had not taken into account ground water pressure.

Kathryn became pregnant and we decided that the apartment would be too small for three children. We had been looking for a home in all areas around Washington and were unable to find any that we could afford to buy. We had very little money for a down payment. I started looking around for a position that would pay more money and answered a want ad listed in the weekly Engineering News-Record magazine. The advertisement was for an engineer to run a testing laboratory in Idaho. I received an answer to my letter from F. C. Torkelson, an engineering firm, located in Salt Lake City, Utah. They requested that I come to Idaho Falls, Idaho for a job interview. It was the first time that I been that far west. F. C. Torkelson had a government contract to do all the surveying, design and construction inspection of projects less than $100,000.00 and do all the construction materials testing required at the National Reactor Test Station (NRTS) located around 40 miles west of Idaho Falls. The firm was looking for an engineer to supervise a testing laboratory as well as the concrete batch plant inspection program.

I returned to Washington and in a few days I received a job offer from F.C.Torkelson that carried a higher salary than what I was making. I went down to Richmond to ask Mr. Doyle, the President of Froehling & Robertson, for a raise. Mr. Doyle, told me that they could not afford to pay any more, so I went back to Washington and accepted the new position. The interesting thing was that I had increased the Washington billings to an all time high and the future earnings looked extremely good. After receiving a confirmation of my acceptance of their offer, I wrote Mr. Doyle resigning my position and giving a month's notice. After three weeks, with no news from Richmond about what to do with the office, I drove down to Richmond to see what they wanted me to do about closing the office or transferring information. I saw Mr Doyle and he stated that he had just read my note and he was sure that we could work things out, but I told him that it was too late as I would be leaving for Idaho next week. I really didn't want to resign, but we needed more money. My old boss in Richmond, Author Lott, was in the hospital and I went by to see him. He had not heard that I was leaving, so I told him about the new position and what they were paying. He told me that in his opinion I was doing the right thing in leaving the Company.

The Doctor gave the approval for Kathryn to travel to Idaho Falls providing we would drive around 300 miles per day. We took our time driving out in June, 1957. It was the first time that we had driven that far west. When we arrived we found out that housing was in very short supply and there was very little to rent or buy in our price range. Our realty agent located a house to rent temporarily until we could buy a home. The large corporations at the site were paying a housing subsidy, which I did not get. We finally located a house to buy, but we had no money. The car was paid for and we had no debts.

The position required a "Q" clearance, that is, a government security clearance. I was cleared by the F. B. I. Based on the security clearance and no debts, I was able to obtain the necessary money from the bank and buy a home. The bank granted us a first and second mortgage on the house plus a loan on the car. We sold the two lots in Richmond and we had to purchase a washer, dryer and refrigerator on time payments. We ended up with a two bedroom home with a full basement and a small yard on 23rd. Street. The house had a bedroom downstairs and had plenty of shelves and cabinets downstairs for storage and a gun room. The previous owners were Mormon and since they believed that a famine would occur, all Mormon homes had plenty of cabinets to store several years of food supplies. It was the first time that we lived in a place where one could buy food items in bulk.

The position required a "Q" clearance, that is, a government security clearance. I was cleared by the F. B. I. Based on the security clearance and no debts, I was able to obtain the necessary money from the bank and buy a home. The bank granted us a first and second mortgage on the house plus a loan on the car. We sold the two lots in Richmond and we had to purchase a washer, dryer and refrigerator on time payments. We ended up with a two bedroom home with a full basement and a small yard on 23rd. Street. The house had a bedroom downstairs and had plenty of shelves and cabinets downstairs for storage and a gun room. The previous owners were Mormon and since they believed that a famine would occur, all Mormon homes had plenty of cabinets to store several years of food supplies. It was the first time that we lived in a place where one could buy food items in bulk.

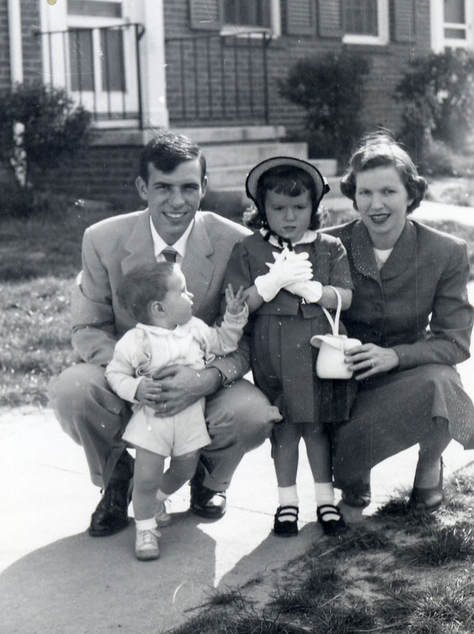

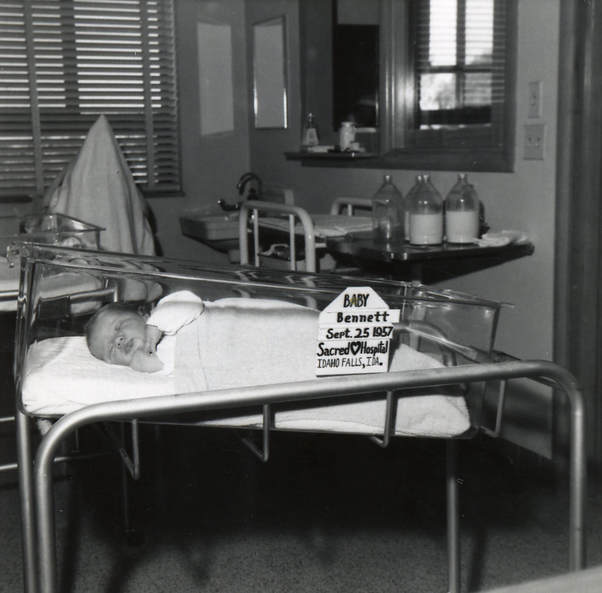

The first picture of Wayne Markham Bennett

The first picture of Wayne Markham Bennett

Idaho Falls was a Mormon town with one Presbyterian Church, a Baptist Church and a Catholic Church and 23 LDS Wards. We joined the Presbyterian Church. The town had two hospitals, one Mormon and one Catholic. The Catholic hospital was located three blocks from our home and Wayne was born in the Catholic hospital on September 23, 1957.

The winter weather was cold and dry. During the winter it would snow about every night and evaporate during the day. The snow would slowly build up and the streets were never plowed. The children ice skated on the irrigation ditches. All of us learned to ice skate. On a clear day one could see the mountains in Yellowstone Park from our house.

The NRTS site was around 40 miles west of town and covered a lot of territory. From the south end to the north end was over 40 miles. All vehicles were equipped with radios to keep in touch with home base at the south end of the site and snake bite kits. We rode a bus to work, and for the first time I had regular working hours. Torkelson's office and the laboratory were located in the south end of the site. The laboratory did all the testing of construction materials for the entire site, and was responsible for all the quality of concrete produced on the site.

The site had several interesting features, one being that in the past there was a Pony Express trail crossing the site and a way station. The trail and the foundation of the way station were still visible. A river ran across the site called the lost river as it went under ground at a certain point. The area had an unusually large underground water reservoir. Shortly after World War I a group of investors laid out a small town on the site. Due to water problems they were unable to generate any sales and the project was stopped, but one could still see the layout of the streets. During World War II the area was used for test firing the large 16 inch guns. They were aimed at large concrete cubes which were scattered around the area. The large cubes were still there. The railroad siding was called Scoville Junction named after the army officer that was in charge of the testing. Several years later after leaving the site I met Mr. Scoville son, John, at Harza Engineering Company. John Scoville ended up as Harza's Chairman of the Board in the early nineties.

The first generation of nuclear electrical power for commercial use was done at the site. All sorts of nuclear testing was ongoing. The research for the nuclear generators to drive the submarines was done on the site. At one time I was working on locating sufficient material for construction of a landing strip for an atomic airplane. General Electric at the north end was working on the atomic motor for the plane.

Jim and a contractor looking for iron ore to make heavy weight concrete

Jim and a contractor looking for iron ore to make heavy weight concrete

I got exposed to the use of heavy weight concrete for shielding. Iron shots can be used as aggregates to produce concrete weighing around 300 pounds per cubic foot vs a normal 150 pounds per cubic foot. The higher density of the coarse and/or fine aggregates affects the mixing and workability of the concrete. The laboratory was involved in investigating the use of various types of heavy weight aggregates with different specific gravity in concrete. The local aggregates produced at the site were reactive, yielding a poor quality concrete in respect to durability. After a few years the reactive aggregates would expand causing cracking and with freezing and thawing in cold weather was destroying the concrete. One of the ways to control an alkali reaction is to used a pozzolan additive, so we started investigating the use of pozzolans to improve the durability of the concrete. I set up a contract for the Corps of Engineers' Troutdale Laboratory, just outside of Portland, Oregon to do a series of special laboratory testing for us. I made several trips to the laboratory to review the work that was being done.

I discovered that Grant County, Washington was using a local pozzolan in the concrete on their Priest Rapids hydroelectric project on the Columbia River. A local contractor that was interested in setting up a pozzolan plant near the NRTS arranged for a trip to the construction site. We flew up and rented a car and drove to the site. It was some distance from a local town. I located the Laboratory Manager, Mr. C. T. Douglas, a retired Bureau of Reclamation's engineer. We spent two days at the site. The contractor was using a local pumice deposit near the dam site. The pumice material was excavated, send through a kiln and the dry material went into a ball mill to achieve a fineness finer than cement. The final product was being used in the concrete at around 20% of the weight of cement. Harza Engineering Company of Chicago, Illinois was the Engineer of Record and they had a small staff supervising the Grant County employees that were overseeing the works of the contractor. We returned to Idaho Falls and I wrote Mr. Douglas a note thanking him for all his help and being a guide around the site.

Bears in Yellowstone Park

Bears in Yellowstone Park

We had a lot of visitors while living in Idaho Falls. Both Kathryn's and my parents drove out to see us at different times. We took a day trip with my parents to Yellowstone Park. Dad had a new Studebaker and while in the park a bear put his paw on the window frame. The window was down and Dad drove away but the bear claws scratched the paint. Don, Kathryn's youngest brother, was in the Air Force and he and Janette, his wife, stopped to see us on their way to his new assignment in Canada.

I went to the annual Spring American Concrete Institution meeting in Chicago in 1958, and heard that Mr. C. T. Douglas had left Grant County and was now in charge of Technical Services on the Niagara Falls Project for the engineering partnership firm of Uhl, Hall & Rich. Messrs Hall, Uhl and Rich were large stockholders in the engineering firm of Charles T. Mann, Company of Boston, MA. The New York engineering laws did not allow a corporation to perform engineering functions in the state. Messrs Uhl, Hall and Rich set up a partnership so that Charles T. Mann could perform the services as called for.

Several months later Mr. Douglas called and offered me a position on his staff at the Niagara Power Project as Manager of Concrete Control. It was a great opportunity for me and the money was very good. After careful consideration and talking it over with my supervisors, I decided to take the offer, even though I really liked living in Idaho.